Gregor Technologies’ 70,000 square foot state-of-the-art manufacturing facility offers a wide range of diverse services, including CNC 5-axis milling, CNC turning, sheet metal fabrication, engineering support, and all levels of contract assembly.

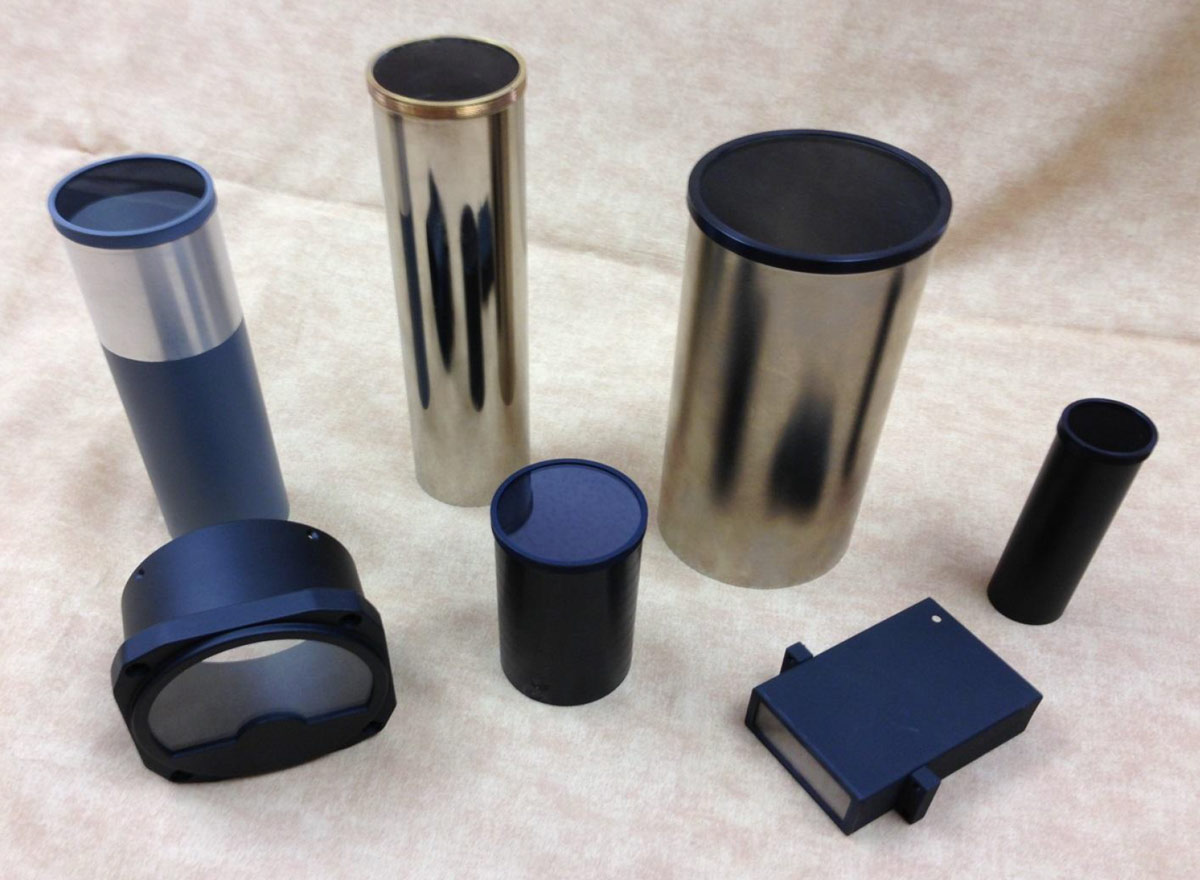

Gregor Technologies is one of the most diversified precision manufacturing companies. We are a full service quality-oriented manufacturing company with a wide range of applications, from precision sheet metal fabrication, cnc turning, 5-axis machining, to full electromechanical assemblies. Our skilled craftsmen work together to provide high quality custom metal products.

All fabrication work is manufactured to suit individual customer requirements and we have access to large stocks via our diverse supplier chain.

Specific Capabilities

- CNC 5-axis Milling: maximum capacity 31″ x 27″ x 20″

- CNC 3-axis Milling: maximum capacity 84″ x 34″ x 30″

- Multi-tasking Twin Spindle-Twin Turret turning centers 8″ diameter

- 6,000 Watt Fiber Laser: sheet capacity 1″ thick mild steel, 5 ft. x 10 ft.

- Contract assembly of electromechanical upper-level finished goods and assemblies

- End of Line (EOL) testing per customer specifications

- ITAR registered

- Surface grinding 12″ x 24″

- ID/OD grinding, 6″ diameter, 18″ long

- Small part lapping and honing

- Wire EDM: 8.5″ max cutting depth

- Laser welding, MIG, and TIG

Fabrication Department

- Amada 6,000 Watt Fiber Laser, with full automation

- Thickness up to: mild steel – 1″, aluminum – 1″, stainless steel – 1″

- Sheet capacity: 5 ft. x 10 ft.

- Mitsubishi 4,000 Watt Laser with shuttle table

- Thickness up to: mild steel – 1″, aluminum – .500″, stainless steel – .500″

- Sheet capacity: 5 ft. x 10 ft.

- Amada 2,000 Watt Pulsar XL laser, sheet capacity: 4 ft. x 8 ft.

- Amada Vipros 255 NC turret punch press, 22 ton, 31 station, sheet capacity 4 ft. x 8 ft.

- (1) Amada ATC HG1003 press brake 10 ft., 110 ton

- (2) Amada 8025 press brakes, 8 ft., 88 ton

- (1) Amada EG6013 press brake 4 ft., 60 ton

- Amada ID40 ST aluminum and carbon steel spot welder

- In‐house MIG/TIG/Laser welding

- (3) Timesave deburring machine 36″ wide, (1) edge rolling machine

- (1) Haeger Auto Pemserter plus 2 manual machines

- (1) 6 foot shear

- Virtek Laser Inspection System

Machining Department

- (14) Hurco CNC vertical machining centers

- Capacity up to 84″ x 34″ x 30″

- (10) Hurco 5‐Axis CNC machining centers

- Capacity up to 31″ x 27″ x 20

- Max RPM: 12,000; rapids: 1,375

Turning

- Multi-tasking twin spindle-twin turret turning centers, 8″ diameter

- (12) CNC turning centers

- Capacity turning centers

- Maximum: 17″ cut diameter, 27″ length

- Live tooling

- Swiss type with 12′ barfeeder (1.250 diameter max)

Inspection Department

- Full CNC Metris LK Evolution CMM

- Capacity: 84″ x 48″ x 36″

- Thermo Scientific Niton XL2 XRF analyzer

- Nikon Horizon 16E Series 11 optical comparator

- Tesa‐hite 700 height gage

We’d Love to Hear From You

Gregor Technologies is the premier high precision machine shop in the northeastern United States. As a vertically integrated, high capacity electromechanical contract manufacturing company, Gregor Technologies is a one-stop shop that has everything needed to take a project from concept to reality.

Contact us today to learn more about our machining, fabrication, and contract assembly services.