Advanced Live Tooling Services in Torrington, CT

Gregor Technologies, an advanced fabrication company in Torrington, CT, specializes in offering top-tier live tooling services. Gregor Technologies is more than a leading metal machine shop; Gregor Technologies is your strategic partner for custom contract manufacturing services of all kinds, providing comprehensive CNC machining services, including precision machining, custom fabrication services, and contract assembly services, all under one roof in its 70,000 square foot facility. If you’re searching for precision machining or custom fabrication services, Gregor Technologies is your answer. Our state-of-the-art facility and expert team are dedicated to delivering high-quality, precise components tailored to meet your specific needs.

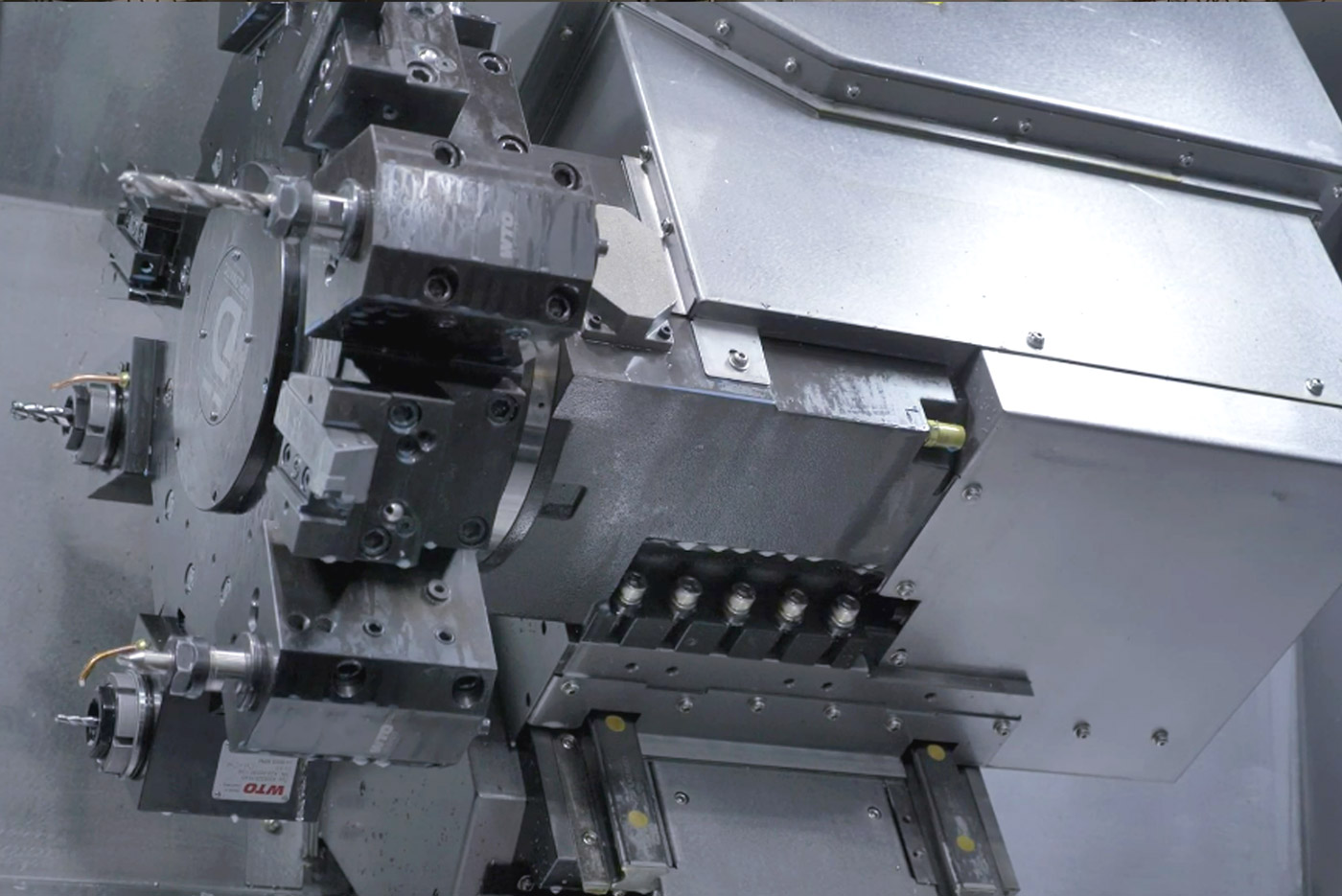

Comprehensive Live Tooling Services

Gregor Technologies’ CNC live tooling services are designed to enhance the efficiency and precision of your machining projects. As a premier CNC machine shop, Gregor Technologies offers a range of services including live tooling lathe operations, CNC lathe with live tooling, and live center lathe capabilities. These advanced services enable us to perform multiple operations such as milling, drilling, grinding, broaching, shearing, tapping, and beveling on a single machine setup. This not only improves accuracy but also significantly reduces production time and costs.

Precision and Quality Assurance

At our precision machine shop, quality is paramount. Gregor Technologies is ISO9001:2015 certified and ITAR registered, ensuring that all our live tooling services meet the highest standards. Our extensive in-house operations and fast, computer-assisted setup times allow us to deliver products from concept to reality efficiently. As a Tier 1 thru 3 supplier, Gregor Technologies offers contract assembly, machining, and fabrication services for clients across New York, Pennsylvania, Connecticut, New Jersey, Maine, Rhode Island, Delaware, Massachusetts, Virginia, and Maryland.

High Capacity Metal Machine Shop

Gregor Technologies operates out of a 70,000 square foot manufacturing facility that is fully equipped to handle high-capacity electromechanical contract manufacturing. This enables us to serve a diverse range of industries, delivering high-quality precision metal products from small sub-assemblies to complex electromechanical units. Gregor Technologies’ diversified precision manufacturing capabilities ensure that there is no limit to what we can fabricate. With dedicated manufacturing cells and extensive in-house operations, we provide exceptional opportunities to control costs and shorten lead times.

Extensive In-House Operations

Gregor Technologies’ vertically integrated high-precision machine shop offers comprehensive services, from raw material processing to final product testing. As a one-stop shop with a 70,000 square foot facility, Gregor Technologies provides custom fabrication services and contract manufacturing services that cater to a variety of needs. Our engineering support services and team of expert craftsmen are committed to delivering high-quality components and assemblies that meet the unique requirements of each client. Whether you need milling services, drilling services, grinding services, broaching services, shearing services, tapping services, or beveling services, Gregor Technologies is equipped to handle it all.

Customer-Centric Approach

Gregor Technologies strives to exceed expectations in every project, and our commitment to quality, precision, and customer satisfaction sets us apart from other live tooling services. Whether you need CNC live tooling, live tooling lathe, or custom CNC lathe with live tooling, Gregor Technologies is ready to help you bring your projects to life with unparalleled precision and efficiency.

Live Tooling vs. Milling Services

Live tooling and milling are both essential machining processes, but they serve different purposes. Live tooling involves the use of rotating tools on a lathe, allowing for operations like milling, drilling, and tapping without the need to transfer the workpiece to a different machine. This is ideal for producing parts with complex geometries and multiple features in a single setup. In contrast, milling is typically performed on a dedicated milling machine where the cutting tool rotates to remove material from a stationary workpiece. While milling is excellent for detailed and intricate parts, live tooling provides the advantage of combining multiple operations, reducing setup time, and improving overall efficiency.

Live Tooling Services

As a leading provider of live tooling services, Gregor Technologies offers precision CNC turning and milling services that are tailored to your specific requirements. Our cutting-edge technology and extensive in-house operations allow Gregor Technologies to provide cost-effective solutions without compromising on quality. Whether you need CNC machining with live tooling, custom CNC turning, milling services, or more, Gregor Technologies is prepared to help you achieve your manufacturing goals.

Contact Gregor Technologies today to learn more about our live tooling services and how our advanced fabrication capabilities can meet your machining needs.

We’d Love to Hear From You

Gregor Technologies is the premier high precision machine shop in the northeastern United States. As a vertically integrated, high capacity electromechanical contract manufacturing company, Gregor Technologies is a one-stop shop that has everything needed to take a project from concept to reality.

Contact us today to learn more about our machining, fabrication, and contract assembly services.