Gregor Technologies, located in Torrington, CT, is more than just a machine shop. We are a leader in providing comprehensive manufacturing process planning services that are tailored to meet the specific needs of our clients. Our expertise in machining, fabrication, and contract assembly allows us to deliver top-quality results across a wide range of industries, including aerospace, defense, medical, and electronics. As a precision machine shop, we specialize in crafting custom components and assemblies with unparalleled accuracy, ensuring that every project we undertake meets the highest standards of quality and performance. With our 70,000 square foot manufacturing facility, we are able to handle even the most demanding production runs, while still remaining a devoted partner focused on delivering results for you.

Comprehensive Fabrication Services

One of the key aspects of our manufacturing process planning is our ability to work with a diverse range of materials. Gregor Technologies offers extensive fabrication services that cater to various material needs, including carbon steel fabrication, stainless steel fabrication, alloy steel fabrication, aluminum fabrication, copper fabrication, and brass fabrication. Our ability to handle these materials with precision and care makes us a go-to partner for businesses in need of reliable metal fabrication solutions. Whether you require custom aluminum fabrication or bespoke stainless steel fabrication, we have the tools, technology, and expertise to bring your vision to life.

Manufacturing Process Planning

Our manufacturing process planning services are designed to optimize every stage of production, from initial concept through to final assembly. We utilize advanced computer-aided process planning (CAPP) systems to streamline workflows and ensure that each step of the manufacturing process is executed with maximum efficiency. By leveraging these tools, we can reduce lead times, minimize waste, and deliver high-quality products that meet your exact specifications. Additionally, our generative process planning capabilities allow us to create detailed, data-driven plans that are tailored to the unique requirements of each project, ensuring that every component is manufactured with precision and consistency.

At Gregor Technologies, we understand the importance of effective assembly process planning. Our team of experts works closely with clients to develop assembly strategies that enhance the efficiency of the production process while maintaining the highest standards of quality. We offer a full range of assembly process planning services, including kanban services, which help to optimize inventory management and ensure that production runs smoothly. Our goal is to help our clients achieve their production targets while reducing costs and minimizing the risk of errors or delays.

Engineering Support Services

In addition to our process planning services, Gregor Technologies provides engineering support services that play a crucial role in enhancing the overall efficiency of the manufacturing process. Our team of skilled engineers works alongside clients to develop customized solutions that address specific challenges and improve production outcomes. We also offer computer-aided drafting and design (CADD) services, including CAD drafting, to review your provided designs and offer input on potential changes that can make for a more efficient the manufacturing process and thus allow you to reduce production costs and potentially price of the final product for expanded market reach. By providing these support services, we help our clients reduce production costs, shorten lead times, and deliver products that exceed customer expectations.

Vertically Integrated Operations

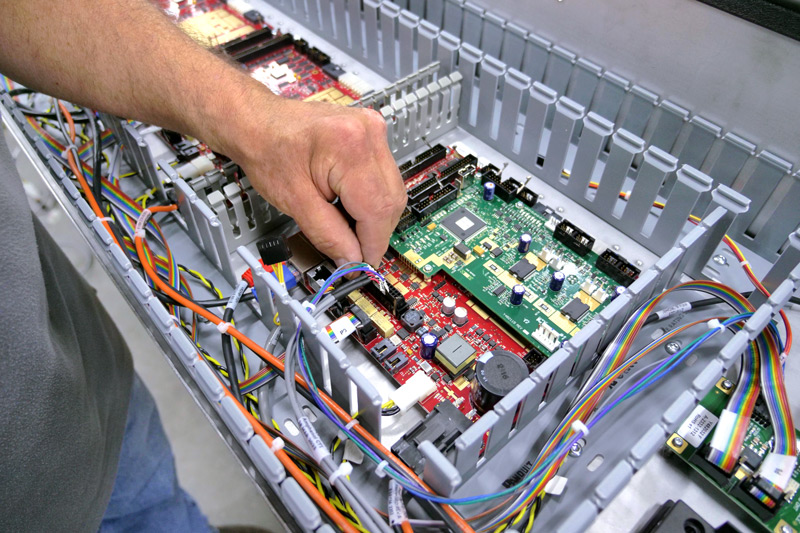

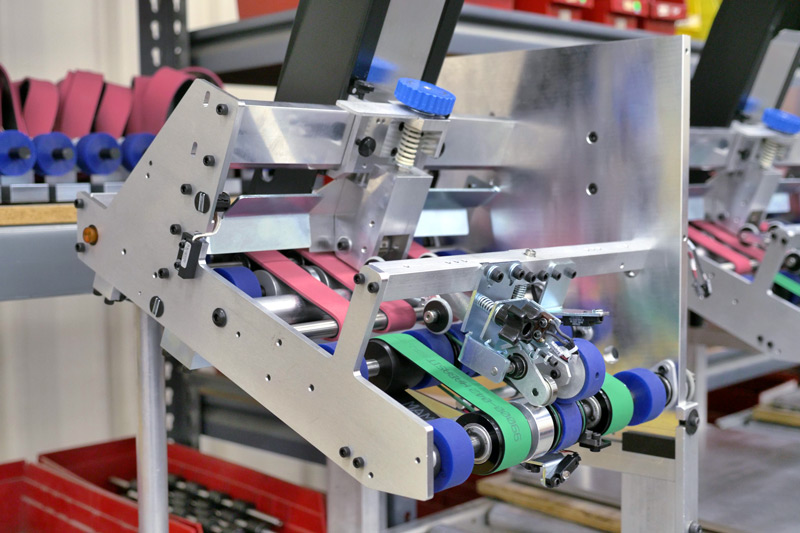

Our vertically integrated operations set us apart from other manufacturers. At Gregor Technologies, we manage every aspect of the production process in-house, from raw materials to final tested products. This integrated approach allows us to maintain strict quality control standards, reduce costs, and deliver a cost-effective product. Our 70,000 square foot manufacturing facility is equipped with the latest technology, enabling us to handle projects of all sizes and complexities. Whether you need small sub-assemblies or complex electromechanical units, we have the capacity and expertise to meet your needs.

As a Tier 1 through Tier 3 supplier, Gregor Technologies is committed to delivering high-quality precision metal products that meet the demands of our clients. We are an ITAR-registered and ISO 9001:2015 certified company, which means we adhere to the highest industry standards in all our operations. Our extensive in-house capabilities allow us to provide a wide range of services, from machining and fabrication to contract assembly, all under one roof.

Contact Us Today

Gregor Technologies offers comprehensive manufacturing process planning services that are designed to optimize production and deliver exceptional results. Our ability to work with a wide range of materials, combined with our advanced planning and engineering support services, makes us the ideal strategic partner for businesses in need of reliable manufacturing solutions. Whether you’re looking for custom machining, fabrication, or assembly services, Gregor Technologies has the expertise and resources to meet your needs and surpass your expectations.

We’d Love to Hear From You

Gregor Technologies is the premier high precision machine shop in the northeastern United States. As a vertically integrated, high capacity electromechanical contract manufacturing company, Gregor Technologies is a one-stop shop that has everything needed to take a project from concept to reality.

Contact us today to learn more about our machining, fabrication, and contract assembly services.